Gain insights into practical strategies that can help your business thrive!

In today’s dynamic global economy, businesses face numerous challenges that demand a relentless pursuit of manufacturing and operational excellence. From supply chain disruptions to economic uncertainties, organizations must navigate through the current struggles to optimize their manufacturing processes and achieve operational efficiency. In this article, we will explore key insights and practical strategies to help businesses thrive in the global economy by focusing on manufacturing and operational excellence.

Embrace Lean Principles for Efficiency

Lean manufacturing principles have proven to be effective in enhancing operational efficiency and reducing waste. By eliminating non-value-added activities, optimizing workflow, and implementing continuous improvement methodologies like Kaizen and Six Sigma, organizations can streamline their manufacturing processes. Encourage employee involvement and empower them to identify and address inefficiencies, leading to improved productivity, reduced costs, and enhanced customer satisfaction.

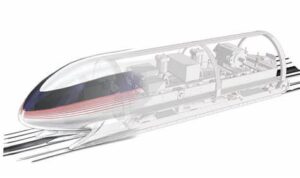

Leverage Advanced Technologies

Technological advancements present significant opportunities for manufacturing and operational excellence. Embrace automation, robotics, and Internet of Things (IoT) to optimize production lines, increase throughput, and improve quality control. Implement data-driven decision making by leveraging real-time monitoring systems and analytics to enhance process visibility and enable proactive problem-solving. Additionally, digital transformation initiatives such as cloud-based systems and enterprise resource planning (ERP) software can streamline operations, improve communication, and facilitate better decision-making.

Focus on Supply Chain Resilience

The global economy’s challenges highlight the need for resilient and agile supply chains. Collaborate closely with suppliers, diversify sourcing, and establish backup plans to minimize disruptions. Implement demand-driven strategies by leveraging accurate forecasting, demand sensing, and predictive analytics. Foster transparency and communication throughout the supply chain to enable proactive risk management and prompt response to changes. By prioritizing supply chain resilience, organizations can mitigate risks and ensure a steady flow of materials for manufacturing operations.

Invest in Workforce Development

A skilled and motivated workforce is crucial for achieving manufacturing and operational excellence. Invest in employee training and development programs to enhance technical expertise and soft skills. Encourage cross-functional collaboration and knowledge sharing to foster a culture of continuous learning. Empower employees to take ownership of their work and provide opportunities for career growth and advancement. By nurturing a skilled workforce, organizations can drive innovation, improve productivity, and create a culture of operational excellence.

Foster a Culture of Continuous Improvement

Operational excellence requires a mindset of continuous improvement throughout the organization. Establish feedback mechanisms and encourage employees to share ideas for process optimization. Implement regular performance assessments, conduct root cause analysis, and identify areas for improvement. Embrace lean tools such as value stream mapping, standardized work procedures, and visual management techniques to drive efficiency and reduce waste. By fostering a culture of continuous improvement, organizations can adapt to changing market dynamics and maintain a competitive edge.

Embrace Sustainability and Environmental Responsibility

In the global economy, sustainability and environmental responsibility are paramount. Incorporate sustainable practices into manufacturing operations by reducing energy consumption, optimizing waste management, and promoting eco-friendly initiatives. Embrace circular economy principles, such as recycling and reusing materials, to minimize the environmental impact. By aligning manufacturing processes with sustainability goals, organizations can enhance their reputation, attract environmentally conscious customers, and contribute to a greener future.

Manufacturing and operational excellence are essential for organizations to thrive amidst the struggles of the global economy. By embracing lean principles, leveraging advanced technologies, focusing on supply chain resilience, investing in workforce development, fostering a culture of continuous improvement, and embracing sustainability, businesses can optimize their manufacturing processes and achieve operational excellence. This holistic approach will not only enhance efficiency, productivity, and profitability but also position organizations for long-term success in the dynamic global marketplace.

The Perfect Planner Team is here if you have any questions about Manufacturing Operational Excellence, and we offer a free consultation service. If you would like to connect with us on this article or any other topic, please message us on LinkedIn, shoot us an email at info@perfectplanner.io, visit our website at www.perfectplanner.io, or give us a call at 423.458.2979.

Author: Thomas Beil

Publication Date: September 18, 2023

© Copyright 2023 Perfect Planner LLC. All rights reserved.